New Recon 400Kg/h Rolling Process Reconstituted Tobacco Sheet Production Line Machine

Introduction:

Rolling Process Reconstituted(Recon) Tobacco Sheet Production is one complete group of equipment which makes full use of tobacco waste such as tobacco stems, powder and dust etc. produced in cigarette manufacturing process. It adopts special technical recipe and flow to finally remake the waste into tobacco Sheet filament.

This production line has the advantages of small investment, environment protection without pollution during manufacturing, reducing cigarette production cost greatly and producing great economic profit.

The production capability of Recon line has four specifications of 200kg/h,400kg/h,600kg/h,800kg/h.

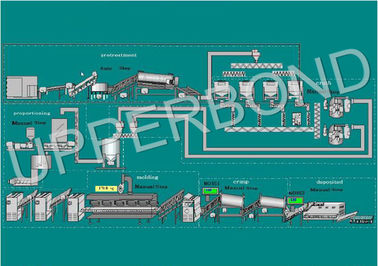

The recon line consist of raw material purifying system, grinding and storing system, powder and liquid material proportioning system, rolling, drying and cutting system, secondary drying and crimping system and the electronic control system.

Main technical parameter:

1,Pretreatment production capacity (before grinding)

2,Production capacity of finished products: 400kg/h (with the moisture of 13%)

3,Thickness of the cut-recon: 0.13± 0.02mm (which can be adjusted by the requirement)

4,Length of the cut-recon: 30~50mm (which can be adjusted by the requirement)

5,Width of the cut-recon:1.0±0.1mm

6,Moisture rate of the finished products:(13±1)%

Requirement of the technical flow and equipment function

System composition:

The LB recon line consist of raw material purifying system, grinding and storing system, powder and liquid material proportioning system, rolling, drying and cutting system, secondary drying and crimping system and the electronic control system.

Technical flow and equipment function:

1,Raw material purifying system

This section will purify and pre-dry the raw material.

1)The raw material mesh should be 2--80mesh after sieving.

2)The moisture should be not more than 10% after pre-drying.

The capability in this section is 800kg/h.

2,Grinding and storing system

In this section, the material will be grinded to micro-powder.

1) After grinding, the material of 80~120 mesh will occupied more than 85%, and the capability here will be 400kg/h.

3,Powder and liquid material proportioning system

This section will complete the powder and the liquid proportioning and mixing.

1)In this section, the material proportioning and mixing will finished by several batches, and the moisture rate will be 30~40%.

4,Rolling, drying and cutting system.

In this section, the material will be rolled to sheet and dried, then cut to tiny sheet.

1)The length of the cut-recon is 30~50mm with 1mm width, which will satisfy the technical requirement of the post-processing. The moisture rate is 17~22%.

5,Secondary drying and crimping system

1)In this section, the cut-recon will be dried for the second time, and then become the finished product. The moisture of the end product is 13%±1%.

6,Electronic control system

The electronic system is the on-site control system, which will control the whole line automatically. The seller will provide the needed sensor/meter and the PLC/HMI.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!